ULTRASONIC CLAMP FLOW METER TUF 2000 TESTING AND TROUBLESHOOTING

Testing the device in ideal and non-ideal requirement, Tips and Trick for Installation Troubleshooting.

We have tested Ultrasonic Clamp Flowmeter TUF 2000 under ideal installation compared with less than requirement conditions to identify whether the device can be used in a nonideal installation. We buy the brand news sensor, the package is consists of a Transducer (TM01 for 50 mm - 700 mm Pipe Diameter), a display unit including integrated transmitter, transducer cable, Clamps, Product certificate, and the Manual Book not including the pasta for the transducers.

|

| Transducer Placement requirement, Source: Screenshot of Cherry Wang Video Youtube Channel |

We use a 12 V adaptor to supply the power, the first test is a basic function, such as display, Menus based on the manual book, Analog Output 4-20 mA for interfacing with Datalogger and strength signal as the installation quality indication.

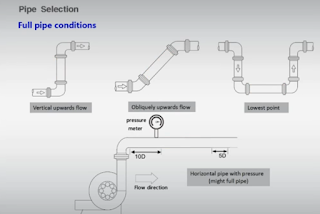

Flowrate measurement needs steady hydraulic flows, we can not measure the turbulence. Based on the Installation Guidance, the Placement of transducers must be at least more than 10 x D (pipe diameter) from the inflow and more than 5 x D from the outflow.

For more reading also knowing trouble shooting and tips, clik the followinmg link:

Komentar

Posting Komentar